- Home /

- ELECTRICAL COMPONENTS /

- CONTACTORS & OVERLOADS /

- CONTACTORS /

- TEND CONTACTOR TC35 15kW/35A 240V COIL

Shop Now

-

HVACR SPARES & EQUIPMENT

- ACTRONAIR & CONTROLS

- SAMSUNG

- EVCO CONTROLS

- EMERSON/COPELAND

- COMMERCIAL KITCHEN VENTILATION

- EVAPORATORS

- CONDENSING UNITS

- CONDENSERS

- BITZER

- EMBRACO

- AIREF

- FRASCOLD

- DANFOSS

- SANHUA

- RANCO CONTROLS

- REGAL

- AXIAL FANS, MOTORS & BLADES

- SYSTEM COMPONENTS

- COMMERCIAL COMPRESSORS

- CONTROLS

- DEFROST CONTROLS

- SKOPE

- KULTHORN KIRBY

- REFRIGERATION HARDWARE

-

HVACR SERVICE TOOLS

- SUPERCOOL HVACR

- RECLAIM UNITS

- VACUUM PUMPS

- LEAK DETECTORS

- REFRIGERANT SCALES

- MANIFOLDS, GAUGES & HOSES

- REGULATORS

- OXY SETS/BRAZING TORCHES/ETC

- DISPOSABLE BOTTLES

- BRAZING

- UV DETECTION/INJECTION KITS

- CHEMICALS

- SUPER SEAL/CLIPLIGHT

- REPAIR PATCHES

- TOUGH TOOL BAGS, VETO PRO PAC

- THERMOMETERS

- HAND TOOLS

- TEST & MEASUREMENT

- GENERAL HVACR TOOLS

- TAPES/GLUES/PAINTS/ACCS'/ETC

- FIRE EXTINGUISHERS

- ADAPTORS & ACCESSORIES

- MISCELLANEOUS

- BLACK DIAMOND TOOLS

- REFRIGERANT & EMPTY CYLINDERS

- COPPER PIPE & FITTINGS

-

AIR CONDITIONING

- AC SYSTEMS

- A SAUERMANN PUMPS

- COPPER FITTINGS

- ASPEN XTRA & ACCESSORIES

- ASPEN PUMPS

- HANWEST CONTROLS

- BIG FOOT SUPPORT SYSTEMS

- CONDENSATE PUMPS

- AIR CONDITIONING FILTERS

- WALL & ROOF BRACKETS

- PVC/PLASTIC DUCT & FITTINGS

- DRAIN PIPE & ACCESSORIES

- MOUNTING FEET & SLABS

- AIR DIFFUSERS & FLEXIBLE DUCTS

- A/C INSTALLATION ACCESSORIES

- COLOURBOND TRUNKING

- UNIVERSAL REMOTES

- THERMOSTATS

- GLYCOL

- TESTO EQUIPMENT

- MECHANICAL SERVICE EQUIPMENT

- ELECTRICAL COMPONENTS

- AUTOMOTIVE

- DOMESTIC REFRIGERATION

-

HEATING SPARES & EQUIPMENT

- BAIN MARIE EQUIPMENT

- HOT WATER SPARE PARTS

-

STOVE/OVEN/GRILL SPARE PARTS

- FAN MOTORS & ACCESSORIES

- THIN COIL ELEMENTS

- MONOTUBE ELEMENTS

- SOLID HOTPLATES

- UNDERGLASS HILIGHT ELEMENTS

- OVEN FAN FORCED ELEMENTS

- OVEN &/OR GRILL ELEMENTS

- BOWLS & PANS

- RINGS & SOCKETS

- DOOR HINGES

- THERMOSTATS

- CONTROLS

- SWITCHES & INDICATORS

- TERMINALS & CONNECTORS

- OVEN KNOBS, CABLES & SEALS ETC

- GAS COOKTOP SPECIFIC PARTS

- MISCELLANEOUS

- EGO

- WATER FITTINGS & ACCESSORIES

- CAPACITORS

- CLEARANCE

-

GENERAL APPLIANCE SPARES

- DISHWASHER PARTS

- DOOR INTERLOCKS

- DRYER PARTS

- FISHER & PAYKEL PARTS

- GE PARTS

- HOOVER PARTS

- HOOVER TWIN TUB

- HOSES, CLAMPS, CONNECTORS ETC.

- KLEENMAID PARTS

- LG PARTS

- MAYTAG PARTS

- MOTOR BRUSHES

- SIMPSON PARTS

- UNIVERSAL BEARINGS

- UNIVERSAL PARTS & ACCESSORIES

- V, DRUM & BLOWER BELTS

- WHIRLPOOL PARTS

- MISCELLANEOUS

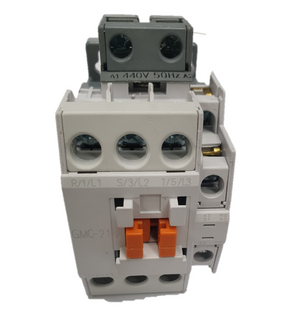

TEND CONTACTOR TC35 15kW/35A 240V COIL

Details

-

In Stock Unit:Each

Description

USER'S INSTRUCTION

ãAttention:

ã. Turn off power before carrying out any maintenance.

ã. Please handle carefully and avoid abnormal vibration and shock.

ã. The dust-proof label on the side of frame must be tear off clearly, if side-mounted auxiliary contact block or mechanical interlock is used.

ã

ã. To dismantle the magnetic contactors which is mounted by DIN 35mm rail, right“-”screwdriver shall be applied and handled in running direction.

ã. A minimum clearance of 8mm and a minimum creepage distance of 12mm has to be ensured by the installation.

ã

ã1. Service Environment

ã1.1 Operational Temperature: -20°c~50°c.

ã1.2 Storage Temperature: -40°c~70°c.

ã1.3 Relative Humidity: 45%~85%.

ã1.4 Altitude: below 2000m.

ã2. Installation and wiring

ã2.1 Ensure that the specifications (Rated power, arrangement of auxiliary contact, rated coil voltage and frequency) meet the requirements.

ã2.2 Mounting positions shall be within the rages specified below.

ã2.3 Select appropriate conductor and tighten with appropriate torque with right tool.

ã2.4 Tightening torques for contactors are given below:

Type | Item | Screw/blot | Tighting torque (kgf.cm) |

TC11 | Main Terminal | M3.5 | 8~12 |

TC16 | Main Terminal | M3.5 | 8~12 |

TC21 | Main Terminal | M4 | 12~20 |

TC30/35/40 | Main Terminal | M5 | 20~25 |

TC50/60 | Main Terminal | M6 | 35~40 |

All Series | Main Terminal | M3.5 | 8~12 |

3.Maintenance:

ã 3.1 Turn off power before conducting any maintenance.

ã 3.2 Disconnect the wires in sequence.

ã 3.3 Dismantle contactor as required for maintenance.

ã 3.4 Assemble and connect the contactor in reverse procedures conducted in steps 3.3and 3.2.

ã 3.5 Check the contactor in a good condition.

ã4.Replacement of the coil:

ãFollow the instructions if replacement of the coil is carried out.

ã 4.1 Dismantle the contactor in appropriate means.

ã 4.2 Replace the coil to requested coil.

ã 4.3 Assemble the contactor in a reverse sequence conducted in step 4.1.

ã 4.4 Check that the contactor can be operated normally.