- Home /

- REFRIGERANT & EMPTY CYLINDERS /

- NON RENTAL CYLINDERS /

- OXYGEN CYLINDERS /

- SPEEDGAS OXYGEN CYLINDER 163CM - SIZE G

Shop Now

-

HVACR SPARES & EQUIPMENT

- ACTRONAIR & CONTROLS

- SAMSUNG

- ACTRON CONTROLS

- EVCO CONTROLS

- EMERSON/COPELAND

- COMMERCIAL KITCHEN VENTILATION

- EVAPORATORS

- CONDENSING UNITS

- CONDENSERS

- BITZER

- EMBRACO

- AIREF

- FRASCOLD

- DANFOSS

- SANHUA

- RANCO CONTROLS

- REGAL

- AXIAL FANS, MOTORS & BLADES

- SYSTEM COMPONENTS

- COMMERCIAL COMPRESSORS

- CONTROLS

- DEFROST CONTROLS

- SKOPE

- KULTHORN KIRBY

- REFRIGERATION HARDWARE

-

HVACR SERVICE TOOLS

- SUPERCOOL HVACR

- RECLAIM UNITS

- VACUUM PUMPS

- LEAK DETECTORS

- REFRIGERANT SCALES

- MANIFOLDS, GAUGES & HOSES

- REGULATORS

- OXY SETS/BRAZING TORCHES/ETC

- DISPOSABLE BOTTLES

- BRAZING

- UV DETECTION/INJECTION KITS

- CHEMICALS

- SUPER SEAL/CLIPLIGHT

- REPAIR PATCHES

- TOUGH TOOL BAGS, VETO PRO PAC

- THERMOMETERS

- HAND TOOLS

- TEST & MEASUREMENT

- GENERAL HVACR TOOLS

- TAPES/GLUES/PAINTS/ACCS'/ETC

- FIRE EXTINGUISHERS

- ADAPTORS & ACCESSORIES

- MISCELLANEOUS

- BLACK DIAMOND TOOLS

- REFRIGERANT & EMPTY CYLINDERS

- COPPER PIPE & FITTINGS

-

AIR CONDITIONING

- AC SYSTEMS

- A SAUERMANN PUMPS

- COPPER FITTINGS

- ASPEN PUMPS

- HANWEST CONTROLS

- BIG FOOT SUPPORT SYSTEMS

- CONDENSATE PUMPS

- AIR CONDITIONING FILTERS

- WALL & ROOF BRACKETS

- PVC/PLASTIC DUCT & FITTINGS

- DRAIN PIPE & ACCESSORIES

- MOUNTING FEET & SLABS

- AIR DIFFUSERS & FLEXIBLE DUCTS

- A/C INSTALLATION ACCESSORIES

- COLOURBOND TRUNKING

- UNIVERSAL REMOTES

- THERMOSTATS

- GLYCOL

- TESTO EQUIPMENT

- MECHANICAL SERVICE EQUIPMENT

- ELECTRICAL COMPONENTS

- AUTOMOTIVE

- DOMESTIC REFRIGERATION

-

HEATING SPARES & EQUIPMENT

- BAIN MARIE EQUIPMENT

- HOT WATER SPARE PARTS

-

STOVE/OVEN/GRILL SPARE PARTS

- FAN MOTORS & ACCESSORIES

- THIN COIL ELEMENTS

- MONOTUBE ELEMENTS

- SOLID HOTPLATES

- UNDERGLASS HILIGHT ELEMENTS

- OVEN FAN FORCED ELEMENTS

- OVEN &/OR GRILL ELEMENTS

- BOWLS & PANS

- RINGS & SOCKETS

- DOOR HINGES

- THERMOSTATS

- CONTROLS

- SWITCHES & INDICATORS

- TERMINALS & CONNECTORS

- OVEN KNOBS, CABLES & SEALS ETC

- GAS COOKTOP SPECIFIC PARTS

- MISCELLANEOUS

- EGO

- WATER FITTINGS & ACCESSORIES

- CAPACITORS

-

GENERAL APPLIANCE SPARES

- DISHWASHER PARTS

- DOOR INTERLOCKS

- DRYER PARTS

- FISHER & PAYKEL PARTS

- GE PARTS

- HOOVER PARTS

- HOOVER TWIN TUB

- HOSES, CLAMPS, CONNECTORS ETC.

- KLEENMAID PARTS

- LG PARTS

- MAYTAG PARTS

- MOTOR BRUSHES

- SIMPSON PARTS

- UNIVERSAL BEARINGS

- UNIVERSAL PARTS & ACCESSORIES

- V, DRUM & BLOWER BELTS

- WHIRLPOOL PARTS

- MISCELLANEOUS

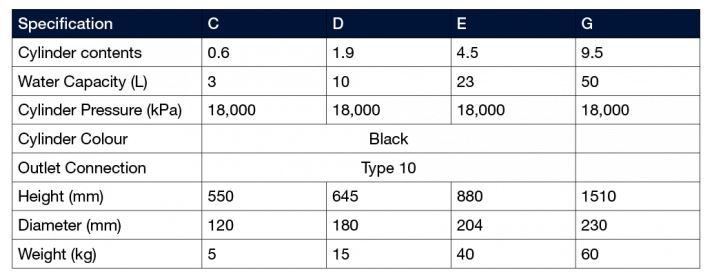

SPEEDGAS OXYGEN CYLINDER 163CM - SIZE G

Stock Code:

CYCO-G

Price:

$738.60 (inc GST)

Quantity Breaks

1+

$738.60 (inc GST)

Details

-

In Stock Unit:Each

Description

The main industrial application of oxygen is combustion.

It is used combined with a fuel gas for cutting, welding, brazing and soldering.

Due to its ability to help stabilise the arc and reduce surface tension, oxygen is used as an ingredient in some shielding gas mixtures.

DANGERS:

• High Pressure compressed gas.

• Vigorously supports combustion.

• Materials that would not normally burn in air, will burn in Oxygen

• Oil and grease are particularly hazardous in the presence of oxygen as they can ignite spontaneously and burn with explosive violence.

Storage and handling

- Store oxygen cylinders away from combustible materials.

- Ensure all cylinders are correctly labelled in accordance with Australian Dangerous Goods Code (Transport)

- Protect cylinders and particularly the valve from physical damage whether cylinder is full or empty.

- Store cylinders in a cool, well ventilated, spark free area below 45°C.

- External storage is preferred.

- Cylinders should never be carried or stored in unventilated areas, vans, cars, garages etc.

- Close valves when not in use and when empty, check regularly for leaks.

- If valve is damaged, do not attempt to operate.

- If valve does not operate by hand, return cylinder to supplier (attach a faulty cylinder tag).

In case of leaks

- Shut off all engines, electrical equipment and other sources of ignition.

No smoking or naked lights. - If possible, use emergency equipment stops.

- Stops leaks if possible, especially in enclosed or inadequately ventilated rooms. Move people from area.

- Check all lines and equipment for leaks, with periodic rechecks. All fittings and connections should be properly fitted.

- If leak continues, move cylinder to a safe area and allow to empty.

- Return empty cylinders and pack to supplier with a note to confirm the leak occurred

- Notify emergency services if required